The market for car wheels is predicted to grow at 5.52% CAGR by the year 2025. The significant aspect that drives the growth of the global wheel market is the product launches that take place by regional and universal car wheel manufacturers frequently. Several manufacturers are adopting innovative approaches to grow the market share of their products.

The success of the new wheel products is expected to accelerate manufacturers for business growth. This blog will help auto part manufacturers understand all the new wheel products that are available in the market and how they will benefit their applications.

What is the Difference Between Wheels and Rims?

The words “wheel” and “rim are frequently used as terms with nearly the same meaning, but technically, they are not the same.

What is a car wheel?

Wheels are the primitive circular parts of a car or motorcycle that rotate in order for automobiles to move forward. The wheels are vertically placed under the car which helps to not only make movements but also provides support to the vehicle to carry heavy loads.

These auto parts are primarily made up of spokes, a disc, and a rim. Spokes are the rods that start from the center disc and go up to the outer ring of the wheel. The disc is the part that attaches the rim to the axle hub. The rim is the part of the wheel that is on the outer edge of the wheel.

Some of the other parts of the wheel include the center bore and a circular space in the center back of the wheel that acts as the hole to which different parts of the vehicle fittings are attached.

What are wheel rims?

The rim of the wheel is simply the outer edge or, the circumference of the wheel where the rubber padding is molded into. One thing that is considered while the size of the wheel is being determined apart from the diameter, is the width of the rim. The car rim designs of the wheel are an important part because it enables the proper fitting between the wheel and the tire.

Relationship

The rim plays an important role in ascertaining the size of the entire wheel. The main function of the rim is to support and seal the tire into the wheel. The rim helps retain the air inside the tubeless tire and ensures its proper fitting. The rim forms an important part of the wheel and without it, the wheel will lose its shape.

What are Aftermarket and OEM Wheels?

What are OEM wheels?

OEM is the acronym for Original Equipment Manufacturer and knowing about OEM and what they can do can make a lot of difference while choosing a brand-new set of wheels. OEM wheels are the ones that are manufactured by the original company of your vehicle and are the exact replicas of the original wheels that came with the car.

If the car wheels are not directly produced by the original car manufacturer, they are made by an independent auto parts supplier with the support and collaboration from the original wheel rims manufacturer. These wheels will be guaranteed to match the exact stipulations of the original company wheels in terms of size, performance, and aesthetic.

What are Aftermarket Wheels?

Aftermarket wheels are those wheels that are manufactured by independent auto wheel manufacturers and are made to perfectly fit multiple vehicles. Any wheel that is not created by the original manufacturer of the vehicle company and is manufactured by a company that is not affiliated with the car manufacturer, is considered to be an aftermarket wheel.

Aftermarket wheel manufacturers are not actually trying to replicate or steal the design of the original wheels and this can be easily seen in the different looks of aftermarket wheels. The major benefit of using aftermarket wheels over OEM wheels is the difference in the overall car wheel cost. Most of the aftermarket wheels offer complete safety and comply with the performance specs that OEM wheel manufacturers also comply with.

Automotive wheel manufacturers design the wheel based on several aspects that are specific to the car such as the weight of the car, how it will be handled, and other significant factors. Aftermarket wheel suppliers generally focus on creating a wheel that is close to the OEM version, but not completely the same.

Wheel Rim Material

Wheel rims are available in a wide range of materials, all of which provide a specific advantage over the other. In the earlier times, wheel rims were manufactured from wooden material and then the metals took over because of the rough road surface. The rim manufacturing process has changed a lot since then. Some of the materials used to manufacture wheel rims include:

1. Car Alloy Wheel

What are Alloy Wheels?

Alloy wheels are wheels that are made from an alloy of aluminum and magnesium to suit the requirements of the automotive industry. Alloys of aluminum or magnesium are light in weight and provide the same strength as steel wheels. They also provide better heat conductions and the look of alloy wheels is very attractive.

Car Alloy Wheel Price

Although the alloy rims are substantially more expensive than steel rims, the car wheel alloy price starts from $50 and may go up to $500 depending on the size and the quality of the materials used.

Pros

1. Attractive Look

The fact that alloy wheels look much more attractive than steel wheels cannot be ignored. Several car alloy wheel manufacturers focus on cosmetic upgrades and improving the visual impact of the wheels, which helps them increase sales.

2. Good Heat Conduction

Alloys are capable of dissipating heat better than other materials used in manufacturing wheel rims and they provide good braking performance, reducing the risk of brake failure.

3. Good Performance

Since car wheel alloy dealers are always on the lookout for better-performing wheels, they choose alloy wheels because they help decrease the unsprung weight and allow the suspension to follow the terrain easily. Additionally, there is a notable improvement in handling the steering.

4. Good Fuel Economy

Alloy wheels are light in weight and that enables them to provide increased fuel efficiency to a considerable extent.

5. Better braking

Alloy wheels provide better braking because it enables better traction because of the reduced wheel hop.

Cons

While alloy wheels from a reliable auto wheel supplier offer benefits in terms of the appearance and performance of automobiles, they are not as durable as steel wheels. Moreover, alloy wheels are costly to produce and repair as compared to steel wheels.

2. Car Steel Wheel

What are Steel Wheels?

The name steel wheels are quite self-explanatory, it means that the wheels are made up of steel. The steel wheels have been around for a long time and are popularly known for their toughness and durability. For this reason, steel wheels are found in most city cars and hardcore SUVs. Steel wheels are often used by car wheel makers as a cost-effective alternative to alloy wheels.

Steel Wheel Price

Depending on the size of the car wheels, the cost of the steel wheels ranges from $30 to $100.

Pros

1. Price of the steel wheels

The steel wheels are manufactured by stamping the wheel into a circular shape, which means that the cost of production is much less than that of alloy wheels.

2. Durability

Steel wheels are much stronger than alloy wheels and that is why auto parts manufacturers find them fit for rugged SUVs.

3. Ease of repair

Steel wheels are comparatively more malleable than most wheels, which makes them easy to repair by simply hammering the bent portion back to shape.

Cons

1. Weight of the steel wheels

Steel wheels are heavy in weight which adds to the unsprung car weight and with the extra weight, the suspension of the car takes a beating after working for a while. However, some automobile companies take advantage of the weight of steel wheels to offer better traction and maneuverability.

2. Corrosion

Steel wheels do not work well in a humid environment because they rust easily. However, with modern paint technology, steel wheels can resist corrosion to an extent.

3. Car Chrome Wheel

What are Chrome Wheels?

There is a common misconception that chrome wheels are made up of chrome, but the fact is that they are simply alloy or steel wheels that have a coating of chrome. The addition of a layer of chrome does not give any benefits to the performance of the wheel but only gives it an aesthetic enhancement. Additionally, it offers excellent protection against oxidation of the wheels

Cost to Chrome Wheels

Depending on the size of the rims and the wheel, the price of a chrome-plated wheel can range from $150 to $300 at least.

Pros

Chrome coating gives the car wheels a mirror-like shine, which adds to the overall aesthetic of the car. It makes the wheel highly robust and resistant to corrosive elements. Chrome wheels are electroplated with metal which makes them stronger.

Cons

Chroming a wheel requires adding several layers of metal to achieve the desired finish, which adds to the weight of the wheel. This can negate the performance advantage that the lightweight wheels have over heavyweight wheels. If the chrome plating isn’t done properly, the metal layer may start to wear away, adding to the repairing costs.

4. Car Fiber Wheel

What are carbon fiber wheels?

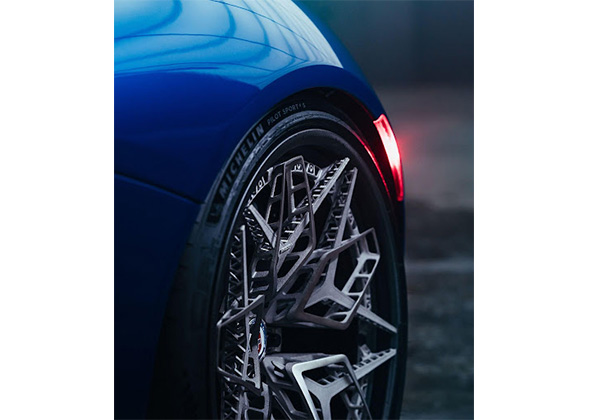

Carbon fiber wheels are wheels that are made up of carbon fiber that helps reduce rotational inertia and the weight of the wheel. This feature helps in increasing the acceleration speed of the car.

Carbon fiber rims price

The price of carbon fiber rims is as high as $10,000 for a pair, which is why they are mostly seen in high-end sports cars that need better acceleration and reduced braking distance.

Pros

1. Lightweight

Automobile wheel manufacturers take advantage of lightweight carbon fiber to improve the performance of the vehicle.

2. Range of options

Because of the lightweight carbon fiber, manufacturers can develop a wide range of designs to suit the requirements of all automobile companies.

3. Improves the aesthetics

Simply put, a set of carbon fiber wheels give an aesthetically pleasing appearance to the car.

Cons

1. Expensive

Even though carbon fiber rims provide better performance to cars and offer several other benefits, their cost is too high for economical cars.

2. Layup Discrepancy

Layup discrepancy decreases the radial and lateral stiffness of the wheel, which leads to the imbalance of the wheel.

How are car rims made?

Car rims are the most simple components of the car, but large wheel rim manufacturing companies are constantly looking for the latest manufacturing techniques and developing the strongest yet lightest rim materials to enhance the performance of the wheels as well as the car. The wheels of the car have a huge technical and aesthetic responsibility that should not be ignored at all.

Forged wheels

What are forged wheels?

Forged wheels are manufactured from a large square piece of solid metal which is heated to extreme temperature and pressurized to form a circular share. Unlike the cast wheels, the surface of forged wheels can be irregular and may need a machining process to make it smooth. The thermal cycle of manufacturing forged wheels helps them be stronger because of grain refinement.

Consistent forging of wheels makes their structural integrity stronger without much material as compared to a cast wheel. However, the process of manufacturing forged wheels is more expensive than manufacturing cast wheels.

The thicker parts of the wheel that require movement of the material use the hot forging method. For forging a complex part of the wheel, wheel rim manufacturers require multiple operations to achieve the perfect shape and each additional step adds to the extra expenses to manufacture the wheel.

The hot forging process starts with a large piece of aluminum that is heated until it melts and then it is placed into the forging press. Next, it is either struck or compressed using a hydraulic press to make a forming die. The wheel rims manufacturer then pulls out the cooled-down part that looks like the shape of the die.

The forging presses create an incredible force in order to move the material in and out of the die. The mechanical presses used to shape the wheel can be three stories tall with half of the machine under the ground. The manufacturing unit is then developed around the press.

The advantage of using forged parts is that the grain structure it produces is highly smooth. The material formed as a result of the forging has long and continuous grains on it. The forged wheel is therefore very strong and lightweight.

Cast wheels

The manufacturing process of the cast wheel involves heating a large chunk of aluminum until it melts into a liquid state. With the use of a vacuum, car parts manufacturers use the molten metal poured into a mold and molded into its final shape. The cast is trimmed and grilled to perfection after it has cooled down. Although the casting process is rapid and affordable, it does result in a weaker material than a forged wheel.

Pouring or vacuuming molten aluminum into a mold that is molded into the shape of the wheel in various dimensions is the casting process. Positive pressure is utilized to accelerate the flow of aluminum alloys into the mold and produce a product with a higher density than a gravity cast wheel. It’s then given time to cool before the minor modifications of drilling and trimming are made.

Because it is quick and affordable, this production method is favored by modern auto parts manufacturers over others. It’s also less time-consuming and inexpensive than other methods. Cast wheels provide a number of advantages in addition to being the less expensive option. There are many different alloys to choose from when it comes to casting wheels.

Casting weight has no restrictions, and the procedure makes it much easier to build intricate parts. A correctly cast wheel can weigh more than a forged wheel, contrary to popular opinion, and the build quality is more than adequate for street and mild track use.

Things To Consider When Sourcing The Right Car Wheels For Your Business

1. Types of your customer base

If you want to serve adventurous people who love to drive out into nature and challenge their vehicles in rough terrain, you can choose steel wheels. Steel wheel rim material is great for people who like off-road driving because they are the strongest amongst the bunch of rim materials.

On the other hand, if your customer base is more leaned towards the look of the car, you can choose alloy wheels. If you serve customers who live in a humid or harsh environment, you should consider alloy wheels because steel wheels can rust easily, especially when they are exposed to humidity.

2. Types of the vehicle you serve

As a car rim manufacturer, the type of vehicles that you serve forms an important aspect of selecting the right car wheels. Race car wheels need to be strong and lightweight, so you can go for carbon fiber rim wheels that offer high acceleration and reduced braking distance. On the other hand, truck rims and motorcycle wheels need the standard specifications that can be achieved by steel and alloy wheels.

3. Aftermarket or OEM wheels

Aftermarket or OEM wheels are other important factors to consider while choosing the right wheels for your customers. Aftermarket wheels offer attractive modifications in the car that help enhance the overall look of the car. However, aftermarket wheels do not provide the same performance as OEM wheels. OEM wheels are a safe choice when it comes to the performance and durability of the vehicle.

4. Budget and Quality

The most important factor to consider as a car rim company is the budget of the wheels. The cost of the wheel should be worth the specifications and performance that the wheel offers. The budget for manufacturing the wheel will determine the quality and performance level of the finished product.

If you are on a tight budget, you can choose steel wheels because they are generally less expensive than alloy wheels and chrome wheels. It is also very cost-efficient to replace or repair steel wheels.

5. Lead Time

The time required to design, manufacture and deliver the wheels is another significant factor that helps determine the right wheel cars for your business. Steel wheels require no extra effort or time to be manufactured, which is why they are the most common choice for automobile companies.

The lead time may not always be a deciding factor if you choose to select a reputable OEM or aftermarket wheel manufacturer for your business that delivers on time for regular orders and gives priority to urgent orders. There are often time-frames attached to delivering the automobiles and the lead time for manufacturing wheels has to be short.

Conclusion

Wheels are the foundation of any vehicle because they support it in multiple ways. The whole weight of a car is supported by its four wheels and the acceleration and braking system of the car also relies on the specifications of the wheel. Depending on your budget and your target audience, you can choose between steel, alloy, chrome, and carbon-fiber wheels.

You can reach out to a well-known auto parts supplier to help you choose the right wheel for your business. Some of the custom wheel manufacturers also offer excellent customizations that help meet the requirements of your customers.