When we talk about wheels, the first image that comes to our mind is of the outer rubber part but here we use the term “wheel” to describe the rim, particularly. Rims not only add to the beauty of your car but they are more than that.

Everyone knows that rims are important for our safety and smooth functioning of the car but only true car buffs know that there are varieties in rims and the wheel production process by which they are manufactured. Let’s take a closer look at how to make rims, here.

What Are Cast Auto Wheels

Cast auto wheels are one of the most commonly found wheels due to the fact that they are less expensive. Their affordability accounts for the reason that they are comparatively easier to make. These wheels offer a good value for automobiles as they are strong and resist heat while being lightweight.

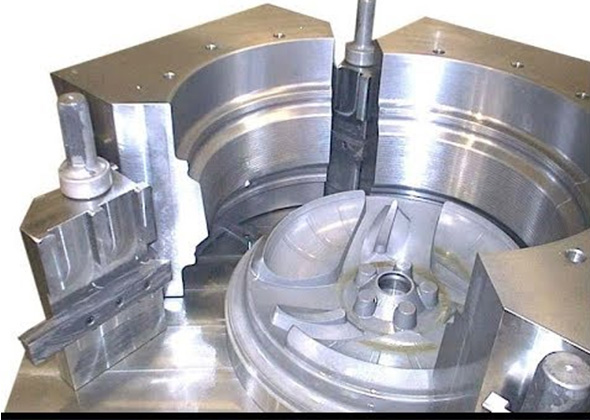

Cast auto wheels are called so since they are formed using a cast or a mold in which the molten aluminum or alloy is poured and solidified. The difference between cast and steel wheels is that the former is more attractive.

Casted Wheel Process

Casting is a relatively less complicated process which makes it more popular in the automobile aftermarket. Aluminum is usually preferred for casting purposes although alloys are also used.

In the casting process, the metal is heated at a high temperature till it gets melted completely. Then, the melted metal is poured into molds that are in the shape of wheels of different dimensions and sizes. Afterward, it is left to solidify.

These casted wheels can be further subdivided into two types: low-pressure cast wheels and gravity cast wheels. After solidification, the wheels are given the finishing touch through trimming and drilling processes.

Low-Pressure Cast Vs Gravity Cast Wheels

Low pressure casting wheels is a process of casting that involves the application of a positive pressure to move the molten metal, most commonly aluminum, into the mold more quickly. The final product using this method is of higher density and better mechanical properties.

Gravity casting wheels is another process of casting where the molten metal, aluminum is the most common although other metals like magnesium can also be used, is molded using natural gravity. These wheels generally have more weight than those of low-pressure casted wheels.

Pros and Cons

The advantages that low pressure and gravity cast wheels offer are:

- There are no complicated processes involved thus, they are easier to make

- They are less expensive and widely popular

- They are lightweight and attractive to the eyes

- They offer strength and gas mileage

- They are readily available and allow more styling flexibility

On the other hand, there are certain disadvantages too which cannot be ignored. These are:

- Casting can lead to inconsistencies in between which can lead to oxidation and makes them brittle

- Casted wheels tend to crack or fail under high pressure.

- They are not good for welding

- They cannot be treated with heat to alter their hardness

Applications

Owing to the fact that casted wheels offer more styling versatility, they are used mainly for the purpose of aestheticism. They are also used to decrease the cost because casting is an inexpensive process as compared to other processes and it is also easier. So, people on a budget usually go for casted wheels.

For automobiles that would be used for normal roads or say, for passenger transportation, both low-pressure casting and gravity casting wheels could offer a great variety. They will be the right choice under normal driving conditions.

What Are Forged Wheel Rims

As identified from the name, forged wheel rims are formed by the process of forging. Forging leads to a positive change in the grain structure. The forged wheel process makes the wheels stronger since their density is increased and porosity is reduced.

They own an elite position since they are forged which is an expensive process that ultimately spikes their prices in the market. Forged wheels only use premium quality aluminum so that the quantity of the metal used is reduced. They are highly customizable which makes them the first choice of several motor racers or car racers. They are available in monoblock, two-piece, three-piece, and multi-piece construction forms.

Forged Wheel Process

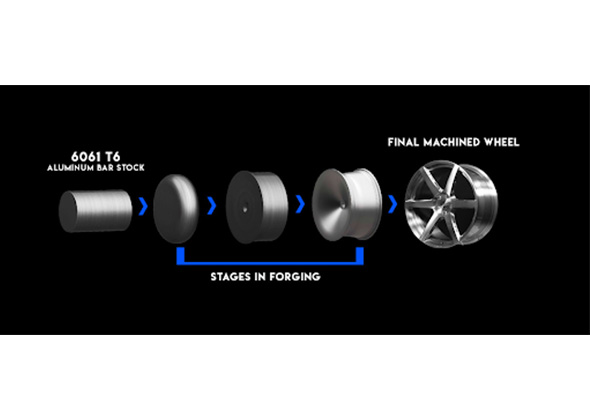

The process of making forged wheels begins with a piece of premium quality metal. This piece is referred to as “billet”. This billet is heated under extreme temperatures and a huge amount of pressure is applied through hydraulic presses to form a raw forging or a raw shape of the wheel.

This raw forging is designed into the desired wheel shape using Computer-Aided Design (CAD).

CNC machining centers then do the work of forming rims and other major design elements. These wheels are then given the final touch by painting, chrome plating, polishing, powder coating, etc.

Pros and Cons

If we compare cast wheels vs forged wheels, the latter undoubtedly have more advantages. These are listed below.

- Forged wheels are exceptionally strong, stiff and corrosion and oxidation resistant

- They are lightweight as less amount of raw material is used in their production

- They make suspension jobs easier, maximize the fuel efficiency and overall performance

- They are highly customizable and thus more desirable by customers

The cons of forged wheels are as follows:

- Since forging is a complex process that requires time, this makes forged wheels expensive as compared to cast wheels

- Although they do not easily surrender to pressure and heat since any type of wheel can get damaged during races, the repairing charges of forged wheels are expensive which makes them less popular amongst customers.

Applications

In cast vs forged wheels, the latter is the first choice of racing drivers and riders at reputed motorsport competitions, who demand maximum performance. This is because they are lightweight and strong at the same time. These wheels are customized in various ways which increase aestheticism. Hence, they are the first choice of luxury car owners.

These wheels are also used for vehicles that are designed for rough, bumpy tracks such as mountain bikes, trucks, and others.

What Are Flow Form Wheels

This is a new concept to enter the wheel industry. Flow form wheels can be defined as a middle ground between cast and fully forged wheels. These wheels combine the positive aspects of the cast and forged wheels but at an affordable price.

Flow forged wheels are strong, stiff, light weighted and have a higher load capacity as compared to cast wheels, and are cheaper than forged wheels. Thus, they provide a middle way between the two. The best part is they are attractive too.

Flow Formed Wheel Process

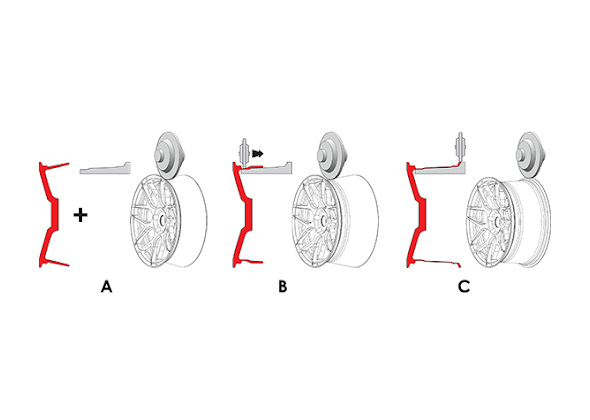

In the flow forming rim process, a pre-low pressure aluminum casting is used rather than starting with raw aluminum. Since it is a low-pressure cast, this casting is heavier at the outer perimeter which is called the “barrel”.

The flow forming process reduces this weight from the barrel. When the wheel is subjected to a huge amount of heat, the rollers put pressure on the barrel area until it is widened to the desired width. During this process, the grain structure of the earlier casted wheel also changes making it stronger but light weighted.

Pros and Cons

The prime advantage of flow form wheels is that it provides an affordable solution to those who cannot afford forged wheels but do not want cast wheels either due to the fact that they are prone to cracking and oxidation. They have more strength and stiffness than cast wheels. They are also lighter in weight which reduces friction and increases overall performance. Flow forged wheels are attractive with outstanding styles.

The cons which flow-formed wheels own is that they still have a cast middle part which gets cracked if subjected to heavy loads. Thus, they are still prone to failures as compared to forged wheels.

Applications

Flow-formed wheels are best to use at places where forged wheels cannot be afforded and cast wheels will not give the desired performance. This paves the way for these wheels which are demanded by customers for automobiles that are not used on a tough track but not on a smooth surface either without compromising on the appearance.

Certain vehicles like the Porsche GT4 use flow-form rims. These wheels are even preferred by motorbike racers like Spec Miata racers and auto crossers. If you want good-quality flow-formed wheels, check for the load rating list on the wheel.

| Cast Wheels | Forged Wheels | Flow Formed Wheels | |

| Manufacturing Process | Two processes: low pressure and gravity casted; molten aluminum is poured into molds, solidified, and designed | Forging is a complicated process than casting; aluminum is mostly preferred though magnesium is also used | A hybrid of cast and forged wheels; a cast aluminum rim is pressurized at the outer edges to make it lightweight |

| Strength Factor | Are strong and stiff; provide gas mileage | Stronger than cast and flow formed wheels; lightweight; fuel-efficient | Lighter and stronger than cast wheels |

| Aestheticism | Styles are available; attractive than steel wheels | Highly customizable; Boosts overall appearance | Customization is possible; offer variety |

| Drawbacks | Prone to cracking and oxidation | Repairing charges are high | The middle part is still cast thus less strong than forged wheels |

| Price | Less expensive than forged and flow formed wheels | Expensive than cast and flow formed wheels | Expensive than cast but cheaper than forged wheels |

Conclusion

The wheel production process can be broadly classified into the cast, forged, and flow forged wheel processes. All these wheels have their own pros and cons and are used in various automobiles depending on the need and affordability.

If you are on the way to selecting a wheel type, then this blog could provide you with the basic differences and necessary information about the three main types of wheels in the industry. But, apart from this, the selection of a wheel also depends on a variety of other factors like the size, type, purpose of the vehicle, etc. These play an important role in determining which wheel type you should go for.