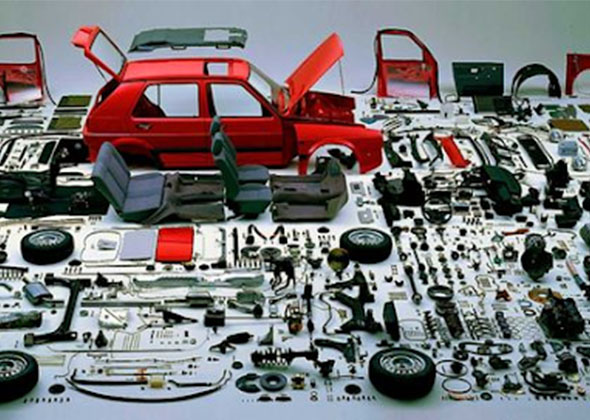

A car is an automobile, where the parts constitute the major part. The main ones from the lot are bonnet, bumper, cowl screen, car lights, quarter panel, etc.

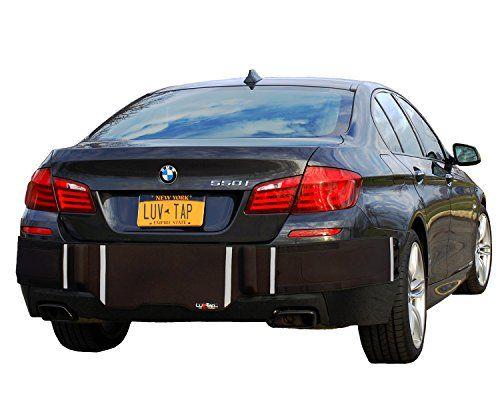

A bumper is a very crucial part of a car. It works as a shield in the rear and front end of the car to protect the car from mirror collision and at times prevent extreme damage.

A lot of things need to be considered before choosing the right car bumper manufacturer in this regard.

Get Custom Bumpers for Wholesales

Businesses that deal with cars have to undergo thorough research to check if the material they choose is perfect for the car.

A lot of things are looked into which include:

- Car Bumper materials

- Car Bumper manufacturing standard and quality

- Market needs (vehicle types, brands, prices, etc)

Car Bumper Materials

ABS or acrylonitrile butadiene styrene is a good thermoplastic polymer for bumpers and it is also a choice when it comes to car exterior.

Secondly, we can also talk about steel front bumper or steel rear bumper. These have many upgraded forms in regard to style and design.

Thirdly, we have another very good choice for bumpers which is a Fibreglass car bumper. It can be shaped in any way it wants to.

Next, we have in the list is Polyurethane or PU material bumper. This one is a very liked choice owing to its strength and durability. Also, we have metal rear bumpers and metal front bumpers which is not a usual choice. But, it is considered in the case of vintage cars.

Last but not least is the Polypropylene bumper which is considered the most frequently used bumper.

Car Bumper Manufacturing Standard and Quality

Quality and standard are other aspects that bumpers ought to meet. As businesses have to look for top-notch quality, they look for fit automotive bumper manufacturers.

- Firstly, the thickness of the wall is one.

- Next, is designing the stiffener and it is not greater than 1/3rd of the wall.

- The holes of the bumper must be placed at points that do not restrict the strength.

- Proper space for hooks should be provided and it must not be in an odd position.

- Energy-absorption blocks should also be checked.

Market Needs

When talking of market needs, we can discuss the same for the popular cars in the market.

Mercedes

The material used for bumpers- Injection-molded semi-rigid plastic

Price for bumpers- $391

Nissan

The material used for bumpers- Polyurethane (PUR), Reaction Injection Molding (RIM), Reinforced reaction injection molding (RRIM), Thermoset polyurethane.

Price for bumpers- $500-$700

Audi

Material used for bumpers- Polyurethane (PUR), Reaction Injection Molding (RIM), Reinforced reaction injection molding (RRIM), Thermoset polyurethane

Price for bumpers- $180

Volkswagen

The material used for bumpers- Polycarbonate.

Price for bumpers- NA

So, when companies look for buying bumpers wholesale, these are the points they take care of.

Get Custom Bumpers for Your Vehicles or Your Business

Now, when the conversation is about retailers, looking for good material and standards is one thing but some tips and tricks can help in attaining one of your choices.

The points that are the most crucial ones are:

- Finalizing the type of bumper

- Using manufacturers part whenever possible

- Building Model

- Building Bumper

- Rust prevention

Finalizing the Type of Bumper

This is your first step in the entire process. Deciding on the type of vehicle, the type of bumper that is the best fit has to be decided. Different types of materials are suitable for different types of vehicles. Studying and knowing about the needs of the concerned car is a matter of concern.

Using Manufacturer’s Part Whenever Possible

Checking the manufacturer’s guide before you start the entire process is advisable. Sometimes, there are guidelines or restrictions that cannot be avoided for the concerned car or vehicle. Apart from this, the mounting brackets, wiring guides, or any other part that can be reused owing to the aspect of the new design should not be thrown out. This saves energy, time, and money.

Building Model

After knowing about all the primitive steps and getting enough knowledge about the bumper, it is time to make the model. Since we are talking of customization in design, the concerned customer can put in his ideas whenever possible and the perfect model can be made.

It is also important to take care that there is no damage to the vehicle owing to the customization. That is why mounting holes are reused so that there is no need of drilling again.

Building Bumper

The most crucial part. The final work needs to be done now. Depending on the choice of the material that has been made, the process for all of them differs. Some of them, such as metal bumpers, need more tools in comparison to something like fiberglass.

Since the model is now in hand, and all the necessary steps are implemented, things are supposed to work smoothly and the customization that has been finalized can come to the scene.

Rust Prevention

Protection is something that has to be followed from the very beginning. It is very crucial to invest in corrosion-resistant materials. After all, if the bumper is made, durability is of concern.

Conclusion

As the discussion here is categorized on two types of buyers, individual buyers and business buyers, it is important to note that both of them have certain points that are needed to be taken care of.

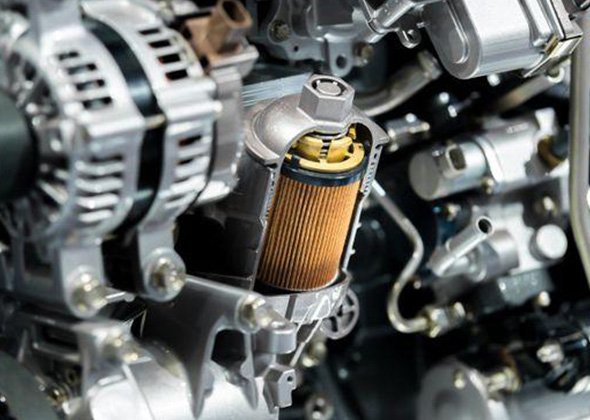

Now, if companies are looking for good such manufacturers, Sunway Autoparts can be of great service. Their product ranges from lights, engine parts, body accessories including bumpers, and all other relevant car parts.

As here the concern is of the bumper, they are one of the top automotive bumper manufacturers in China working in accordance with OEM measurement. Hence, a perfect fit for car companies to hire them.