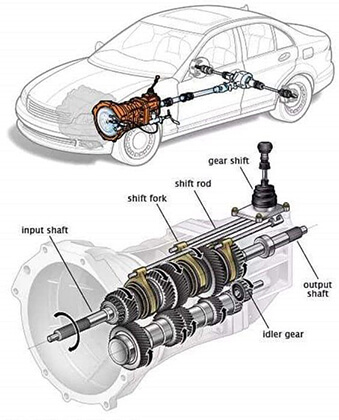

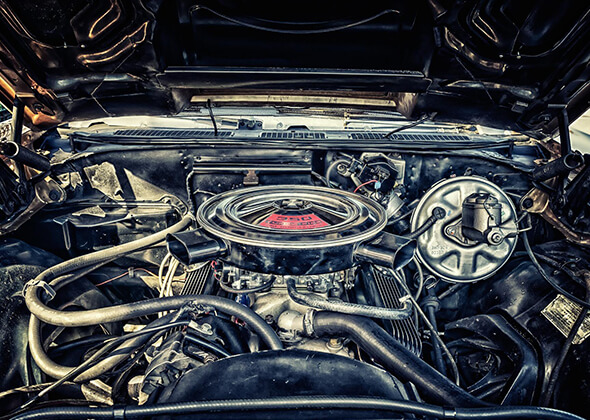

One of the most important components of a car is the transmission. Car transmissions come in a variety of styles. Some are automated, whereas manual transmissions necessitate additional procedures for the vehicle to function correctly. Where is the transmission located? Transmission is usually situated in front of a vehicle’s chassis.

The transmission disables the engine from the driving wheels when the vehicle comes to a complete stop, enabling the engine to rest while the wheels are not moving. Transmissions also allow for swift acceleration from a stop and let the engine run at a lower RPM to reduce wear while the vehicle is traveling at a constant pace.

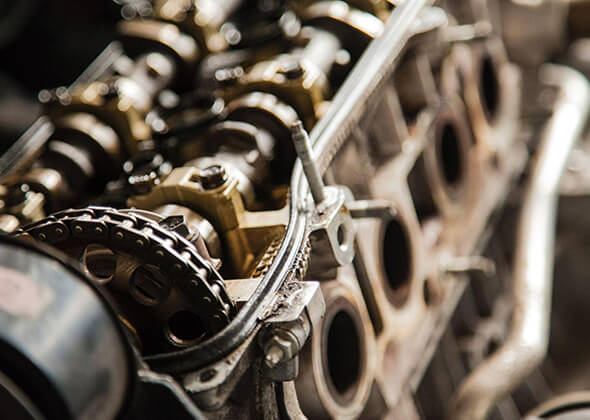

What Is A Car Transmission System?

A transmission, often known as a gearbox, is a mechanical system of gears and gear trains that conveys power generated by an engine to the wheels. A transmission helps a driver to apply power to a vehicle in a controlled manner; without it, the vehicle would not be able to move efficiently.

Lower gears in a gearbox offer the necessary torque for acceleration, whereas higher ratios aid in achieving high speeds by more effectively utilizing the engine’s power. While the purpose is straightforward, there are several types of transmissions that aid in the transmission of power. There are different types of car transmission systems, which we have discussed below.

- Manual Transmissions

A clutch pedal and a shifter are used by the driver to manually change ratios in manual transmissions. These transmissions have a series of gears that run along two shafts called the input and output shafts.

What is the purpose of a manual transmission? The driver of a manual transmission must pick the appropriate gear and engage or release the clutch. A flywheel, pressure plate, and clutch engage and disengage the engine from the transmission.

The flywheel and pressure plate are connected to the engine. The clutch is splined to the transmission input shaft and sandwiched between them. The expression “push in the clutch” refers to disengaging the clutch from the engine by releasing the pressure plate. We must first activate the clutch before making a shift.

- Automatic Transmissions

What is the mechanism of an automatic transmission? The fundamental difference between an automatic and a manual transmission is that the mechanism that powers a manual transmission occurs within the transmission itself in an automatic transmission. Clutches are rarely used in automatic transmissions. Instead of changing gears, the automatic transmission uses a torque converter.

Since the early 1900s, the first automatic gearbox, which was more like a semi-automatic transmission because it still featured a clutch, has existed in some form. The Hydro-Matic automatic transmission was first utilized in a production car in a 1939 Oldsmobile for the 1940 model year. Earl Avery Thompson was the creator. Traditional automatic transmissions are found in most large SUVs and trucks.

How about electric vehicles? Electric vehicles employ single-gear transmissions. Engineers can employ tiny single-speed gearboxes to deliver power to the drive wheels because of the power band of an electric motor. This can be built into the motor or added afterward.

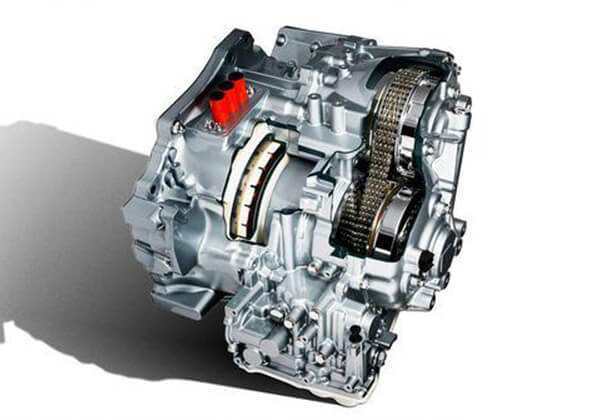

- CVT Transmissions

CVTs, or continuously variable transmissions, are pulley-based gearboxes that are typically seen in compact vehicles with modest engines. Snowmobiles, ATVs, and side-by-sides, to mention a few, have all used CVTs for years. They’ve recently become more prevalent in hybrid vehicles.

A tiny primary drive and a secondary large driven clutch are connected by a belt or chain in the basic setup. When stopped, the belt or chain will be low in the primary drive and high in the secondary drive. The primary drive contracts as the driver speed, forcing the belt or chain to walk up, while the secondary drive expands, causing the belt or chain to move down.

Eight Major Auto Transmission Parts

Here we have mentioned 8 major parts of transmission below.

- Clutch

- What Is A Clutch?

A clutch is a piece of machinery that engages and disengages power transmission, often from the driveshaft to the driven shaft. The clutch joins and disconnects two rotating shafts in the most basic application (driveshaft or line shaft).

The clutch is the most crucial component of an automobile’s engine. When required, a clutch transfers rotating motion or torque from one shaft to another. The engine produces very little torque at low speeds. As a result, starting the engine when under load is difficult.

- Parts Of Clutch

- Flywheel

The flyWheel is a component of the engine that also functions as a clutch. It is a drive element that is housed in a flywheel with bearings and links to the clutch shaft’s pressure plate. The flywheel rotates in tandem with the engine crankshaft.

- Pilot Bearing

The pilot bearing or bushing is placed into the end of the crankshaft to sustain the end of the transmission input shaft. When the clutch is released, the pilot bearing keeps the transmission shaft and clutch disc from bouncing up and down.

- Disc Plate

A disc Between the flywheel and the friction or pressure plate is a plate. To increase friction, it features a sequence of facings inverters on each side. Asbestos is used to make these clutch facings. They’re well-worn and resistant to heat.

- Pressure Plate

Special cast iron is used to make the pressure plate. It is the clutch assembly’s heaviest component. The major function of the pressure plate is to maintain even contact with the driven plate facing, enabling the pressure springs to generate enough force to transmit the full torque of the engine.

- Clutch Cover

The clutch cover assembly is attached to the flywheel by bolts. A pressure plate, release lever mechanism, clutch cover, and pressure springs are all part of it. The clutch plate usually spins with the flywheel.

- Release levers

Their outer ends locate and position on pressure plate legs, while their inner ends project towards the clutch shaft, and they pivot on pins to the clutch cover.

- Clutch Shaft

It’s a part of the transmission. Because the hub of the clutch plate, which is moving on it, is a splined shaft. The clutch shaft has one end that connects to the crankshaft or flywheel and the other end that links to or is a part of the gearbox.

- Clutch Function And Working Principle

It is defined as a system that is used to connect or disconnect the engine from the rest of the transmission elements. It is located between the engine and gearbox. During normal running and stationary position, it is always in the engaged condition.

It disengages when the driver processes the clutch pedal. The clutch disengages for starting, changing gears, stopping, and idling. When the clutch engages, the engine will connect to the transmission, and power flows from the engine to the rear wheels through a transmission system.

When the clutch disengages by pressing the clutch pedal, the engine will disengage from the transmission. Thus, the power does not flow to the rear wheels while the engine is still running.

It is based on the friction principle. When the clutch is not engaged, the driving shaft A with flange C is rotating at ‘N’ rpm, and shaft B with flange D is keyed to the driven shaft, which is stationary. An external force is now imparted to flange D, causing it to collide with flange C. As soon as they make contact, friction between them unites them, and flange D begins to rotate with flange C. The friction between surfaces C and D determines the rotational speed of flange D, which is proportional to the external force applied.

If the force grows steadily, so will the pace at which the force is communicated. The torque imparted by the friction clutch is determined by the flange pressure, surface material coefficient of friction, and flange radius. The force transmitted can be increased by altering any of them.

- Torque Converter

- What Is Torque Converter?

A torque converter is a form of fluid coupling that allows the engine and transmission to spin independently. Because the amount of torque passed through the torque converter is very little while the engine is rotating slowly, such as when the car is idling at a stoplight, keeping the car motionless requires only light braking pressure.

- Parts of Torque Converter

- Torque Converter Pump

The torque converter’s casing is connected to the pump, which is connected to the flywheel. It causes the fluid inside the casing to travel in the opposite direction of the casing’s rotation.

- Turbine

The turbine, which is located in front of the pump and closer to the flywheel, drives the output shaft. To absorb the torque and move the output shaft, it rotates in the opposite direction as the fluid rotates.

- Stator

The job of the stator is to guarantee that the fluid direction after it exits the turbine is proper. In this scenario, the right direction is the same as the pump’s direction.

- Torque Converter Function And Working Principle

The torque converter’s casing is attached to the engine’s flywheel. This causes the casing to revolve at the same speed as the engine. Because the pump is attached to the casing, it rotates at the same rpm and in the same direction. There is fluid inside the casing, which is thrown around by the centrifugal force of the pump.

This fluid is then directed into a turbine with small grates. The fluid can pass through these grates and move the turbine. The turbine begins to rotate after absorbing the torque. The output shaft is directly attached to the turbine.

When the fluid exits the turbine, it has essentially no momentum and is moving in the opposite direction of what the pump wants. As a result, the stator is used. It changes the direction of the fluid to match the pump’s specifications. This completes the cycle that continues to rotate in order to move the car.

- Planetary Gear Parts

- What Are Planetary Gear Parts?

Planetary gears are employed in gearboxes that power anything from basic plant machinery to cutting-edge electric vehicles, and they are at the heart of modern engineering. Thousands of years ago, the simple structure of a central drive and orbiting gears were developed to imitate the movements of the planets. Planetary gears are now used in applications requiring great torque density, operational economy, and durability.

- Parts of planetary gear

- Sun gear (central gear)

The sun gear drives the surrounding planetary gears in a planetary gearbox, which are mounted to a carrier to avoid slippage during operation. The planetary gears rotate the ring gear while the sun gear is powered.

- Multiple planet gears

The epicyclic gear is usually made up of two gears, one of which meshes with the sun gear and the other with the planetary ring gear. These are used to slow things down. They are used to boost torque and slow down motors.

- Ring gear (outer gear)

The load from the sun gear is divided into many planet gears that drive the outer ring, shaft, or spindle, respectively. The ring gear rotates in the same direction as the sun gear, giving reversal.

- Planet carrier

The planet carrier is home to the planet gear, which rotates in the opposite direction as the planet carrier. It usually connects the centers of two gears and helps them roll without slipping.

- Planetary Gear Function And Working Principle

Power transfer is only possible through a planetary gear set since each member can revolve or be held at rest. The two members are locked together since one of them is at rest. Neutral conditions exist when no member is detained or locked. Any one of the three members can be employed as the driving or input member while the third member is maintained immobile.

The planetary gear set produces either a torque increase or a speed increase depending on which member is the driver, which is held, and which is driven. Furthermore, the output direction can be reversed using a variety of combinations.

Both the ring gear and the sun gear are input members in the combinations; they rotate clockwise at the same speed. The internal teeth of the clockwise rotating ring gear try to rotate the planetary pinions clockwise as well, but the sun gear, which rotates counterclockwise, tries to drive the planetary pinions counterclockwise. These opposing forces lock the planetary pinions against rotation.

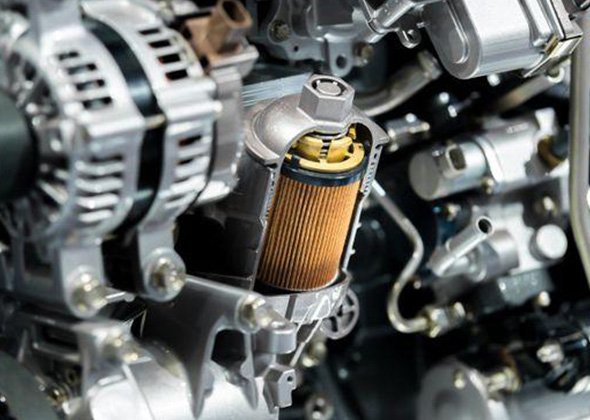

- Automatic Transmission Oil Pump

- What Is An Automatic Transmission Oil Pump?

The automatic transmission in a car has a lot of moving parts that require not only good lubrication but also good cooling. The transmission lubrication system, which is centered on the transmission oil pump, handles all of this. With the increasing RPM rate of the engine shaft, this efficient transmission component helps to maintain the appropriate system pressure and boost lubrication efficiency.

- Parts Of An Automatic Transmission Oil Pump

Automatic transmissions are currently supplied with two types of oil pumps:

- Gear Oil Pump

- Vane Pump

Each one of these types of oil pumps has its own set of advantages and disadvantages. Most modern transmissions are now equipped with innovative pumps that ensure that the lubricating system maintains the proper pressure.

- Automatic Transmission Oil Pump Function And Working Principle

The engine shaft is intrinsically linked to the oil pump. It’s made to deliver oil under pressure, which is used in automatic transmission for a variety of tasks. Because the oil pump is subjected to high loads during operation, transmission repair specialists are regularly faced with oil pump issues. These issues could result in the component’s entire inability to function or a pressure drop in the lubricating system.

Modern automatic transmissions, which are equipped with multiple sensors, can monitor the system pressure and alert the driver if the pump is malfunctioning. The problem with the pump is usually fixed by replacing the faulty component.

- Transmission Oil Pan

- What Is A Transmission Oil Pan?

Automatic transmission fluid is kept in the transmission and off the ground by the transmission oil pan and gasket. If the pan itself is not damaged, repairing a transmission pan leak is generally as simple as replacing the pan gasket. Removing the transmission pan may also allow the driver to inspect and repair the internal components of the transmission.

The transmission oil pan can be damaged by a variety of things, including speed bumps and curbs. If the gearbox is leaking due to damage to the pan, the old pan will need to be replaced.

- Transmission Oil Pan Functions And Working Principle

The pan serves two purposes. The pan retains automatic transmission fluid while it’s connected to the transmission. When the pan is removed, the transmission’s internal components can be accessed without having to dismantle the remainder of the transmission.

During service, the transmission pan may have a drain plug or the pan may need to be removed and drained. When the transmission pan is removed from the vehicle, the pan gasket must be changed.

The ATF is stored in the transmission pan and is used to provide fluid pressure, lubrication, and cooling for the automatic gearbox. Aside from confining the fluid, the pan has other key functions, including:

- Prevent contamination of the fluid.

- Remove the ATF from the transmission and cool it.

- The gasket in the transmission oil pan prevents fluid leakage.

- Use the pan’s magnet to collect dirt and other particles in the ATF.

- Prevent a leak on the road from debris(like a rock).

- Brake Band

- What Is A Brake Band In An Automatic Transmission?

An automatic transmission brake band shifting system. Automatic Transmission Flexible steel plates lined with organic (cellulose) or semi-metallic friction substance make up brake bands. To aid with heat dissipation, the liner absorbs transmission fluid.

- Parts Of A Brake Band In Automatic Transmission

The planetary gear control system includes the brake band, as well as friction discs, a one-way clutch, and other components. The automatic transmission brake band is required to temporarily block planetary gear elements. Metal is lined with organic friction material in the composition of the bands. This element either locks or unlocks the ring or sun gear. A hydraulic unit is in charge of its operation.

- Brake Band Function And Working Protocol

The band is mounted on the gearbox casing, with one end of the band connected to the casing and the other end connected to a servo unit running piston. The operation of the drum half of the clutch pack with the planet gear of the other half of the clutch pack is directly affected by changing the band state. Automatic transmissions shift gears in accordance with the RPM rate in this manner.

The notion of operation is similar to multiple clutch discs and one-way clutches, and a band serves as a reaction mechanism. However, there is one important distinction. A transmission band is essentially a stopping and holding component, whereas clutches are used to hold and run planetary gear set pieces.

- Transmission Brake Band

- What Is A Transmission Brake Band?

Steel bands that wrap around components of the gear train and connect to the housing area are known as transmission bands. Transmission fluid is forced out of grooves carved onto the band’s surface when the band tightens around the drum. The drummer comes to a complete stop and remains there.

- Parts Of A Transmission Brake Band

Single or double wrapped bands are available. To obtain the same stopping power as a single band, double wrapped bands have a stronger gripping force and require less hydraulic pressure.

- Transmission Brake Band Function And Working Protocol

The band is attached to the gearbox case on one end and connected to a servo unit running piston on the other. Changing the band state has a direct impact on the operation of the drum half of the clutch pack with the planet gear of the other half of the clutch pack. Automatic gearboxes do this by shifting gears in accordance with the RPM rate.

Multiple clutch discs and one-way clutches are similar in concept, and a band serves as a reaction mechanism. There is, however, one significant distinction. Transmission bands are used to stop and hold planetary gear set components, whereas clutches are used to hold and run them.

- Transmission Output Shaft

- What Is A Transmission Output Shaft?

The driving wheels are connected to the automatic gearbox in the car through an output shaft. The output shaft is the part of the transmission that transmits power to the wheels.

The output shaft will rotate at the speed the driver specify, based on the speed the driver choose and the gear that the automatic transmission sets. The output shaft normally rotates at a slower pace than the input shaft in order to keep the wheels turning at a reasonable and safe speed.

- Transmission Output Shaft Function And Working Protocol

The output shaft, often known as the main shaft, extends from the back of the transmission. The transmission’s main shaft and input shaft are connected by a line that runs from front to back. They appear to be the same shaft, yet they are actually two separate shafts.

The tiny bearing from the back of the input shaft supports the front of the main shaft. The vehicle’s torque is provided by the main shaft, which rotates at various rates. The gear or synchronizer can be manipulated for engagement and disengagement because it is a splined shaft.

To keep the vehicles safe and manageable, the output shaft allows the vehicle to go at a fraction of the automatic gearbox’s speed. Because the gearbox may adjust the speed ratio between the input and output shafts, you can think of the output shaft as having a greater range of speed.

Conclusion

Regardless of the situation, the transmission guarantees that the engine spins at an optimal rate (neither too slow nor too fast) while simultaneously giving the right amount of power to the car wheels to move and stop the automobile. It sits between the engine and the rest of the drivetrain and functions as the vehicle’s power switchboard.

While you may not be familiar with all of the components of the transmission or how they function together to keep the car operating, knowing the basics can help you detect if there is a problem or enriching your knowledge when selling auto parts.

Sunway is one of the biggest auto transmission parts suppliers and OEM auto parts in China. They are also car clutch manufacturers who have torque converter parts and planetary gear functions. So, if you are looking for custom bulk orders, you can contact Sunway.